Building Tomorrow, Responsibly

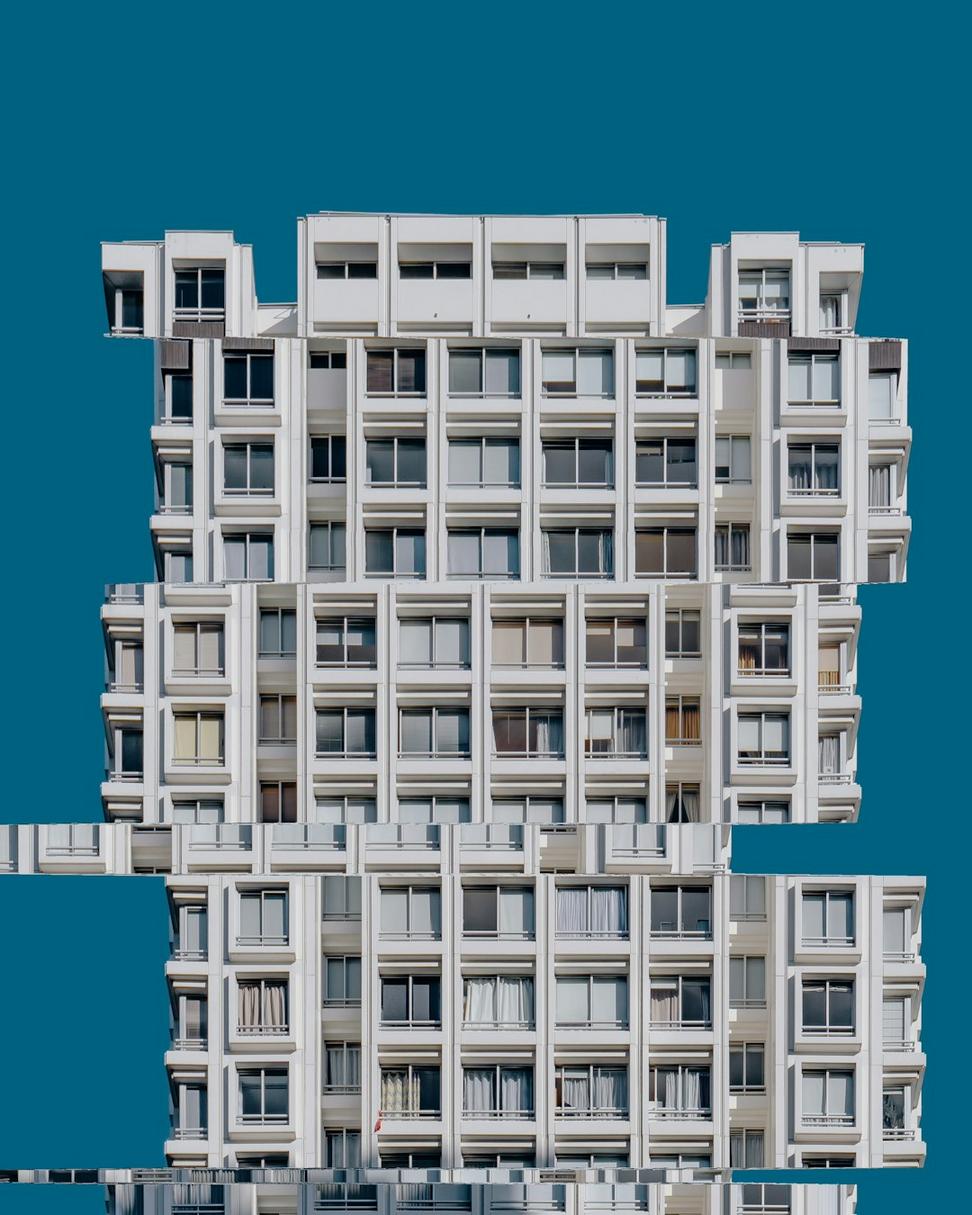

Look, we're not gonna pretend we've got all the answers. But we've been in this game long enough to know that every choice we make today matters. From the materials we spec to the orientation of a single window—it all adds up.